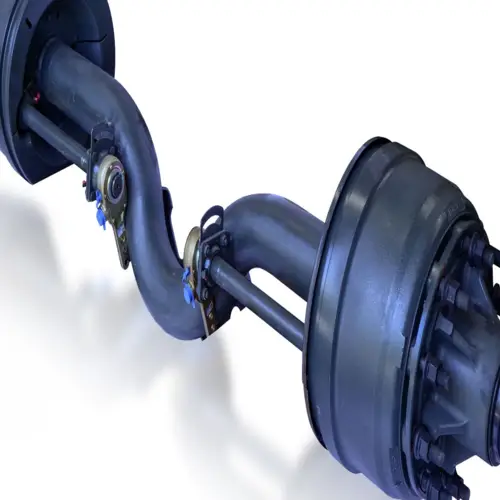

German Type 16t Assemble Truck Rear Steer Axles for Trailer

The German Type 16t Assemble Truck Rear Steer Axles for Trailer are high-quality trailer axles that are designed to provide superior performance in a variety of applications. These axles are made from top-quality materials and are built to last, ensuring that your trailer will provide reliable service for years to come.

Product Description

The China best American Type Axle Rear Steer Axle air compressor for car and Manufacturer 8t-25t American Inboard Built-in Brake Drum Axle for Trailer truck is a highly versatile and reliable piece of equipment that is ideal for a wide range of applications. It features a range of advanced design features and technologies that make it one of the most advanced trailer axles on the market today.

Features and Benefits

- High-quality construction materials

- Advanced design features and technologies

- Superior performance and reliability

- Designed to provide long-lasting service life

- Easy to install and maintain

Specifications

The China best American Type Axle Rear Steer Axle air compressor for car and Manufacturer 8t-25t American Inboard Built-in Brake Drum Axle for Trailer truck is available in a range of different specifications to suit the needs of a variety of different applications. Some of the key specifications of this product include:

| Axle Type | Max Capacity(t) | Track(mm) | Brake(mm) | Spring Seat Installation | Axle Beam(mm) | Centre Distance Of Brake Chamber(mm) | Wheel Fixing | Total Length(mm) | Recommended Wheel | Axle Wright(kg) | ||

| Stud | P.C.D(mm) | H(mm) | ||||||||||

| JS08Y2C15 | 8 | 1850 | 420*150 | >=1080 | 127 | 428 | 10*M22*1.5 ISO | 335 | 280.8 | ~2145 | 7.5V-20 | 323 |

| JS13Y9C10 | 13 | 1840 | 420*180 | >=970 | 127 | 380 | 10*M22*1.5 ISO | 335 | 280.8 | ~2180 | 7.5V-20 | 342 |

| JS13F1B10 | 13 | 1840 | 420*180 | >=930 | 150 | 380 | 10*M22*1.5 ISO | 335 | 280.8 | ~2180 | 7.5V-20 | 340 |

| JS14F1B11 | 14 | 1840 | 420*220 | >=930 | 150 | 340 | 10*M22*1.5 ISO | 335 | 280.8 | ~2180 | 7.5V-20 | 358 |

| JS15F6B11 | 15 | 1850 | 420*180 | >=940 | 150 | 390 | 10*M22*1.5 ISO | 335 | 280.8 | ~2200 | 8.0V-20 | 370 |

| JS16F6B11 | 16 | 1850 | 420*220 | >=940 | 150 | 350 | 10*M22*1.5 ISO | 335 | 280.8 | ~2200 | 8.0V-20 | 388 |

| JS20F8B12 | 20 | 1850 | 420*220 | >=940 | 150 | 345 | 10*M24*1.5 ISO | 335 | 280.8 | ~2247 | 8.0V-20 | 430 |

| JS25H8B12 | 25 | 1850 | 420*220 | >=940 | 150 | 340 | 10*M24*1.5 ISO | 335 | 280.8 | ~2215 | 8.0V-20 | 474 |

Detailed Photos

Packaging & Shipping

We offer a range of packaging and shipping options to suit the needs of our customers. Our products are carefully packaged to ensure that they are delivered to our customers in perfect condition, and we work closely with our shipping partners to ensure that our products are delivered on time and at a competitive price.

Frequently Asked Questions (FAQs)

1. What is the load capacity of the China best American Type Axle Rear Steer Axle?

The load capacity of the China best American Type Axle Rear Steer Axle varies depending on the specific model. Please refer to the specifications table for more information.

2. Is the China best American Type Axle Rear Steer Axle easy to install?

Yes, the China best American Type Axle Rear Steer Axle is designed to be easy to install and maintain. However, we recommend that installation be carried out by a professional mechanic to ensure that the axle is installed correctly and safely.

3. What kind of materials are used to make the China best American Type Axle Rear Steer Axle?

The China best American Type Axle Rear Steer Axle is made from high-quality materials that are designed to provide superior strength, durability, and performance. These materials include top-quality steel, aluminum, and other alloys.

4. What kind of maintenance does the China best American Type Axle Rear Steer Axle require?

The China best American Type Axle Rear Steer Axle is designed to be low-maintenance, but regular inspections and maintenance are recommended to ensure that the axle is functioning properly and to prevent damage or wear.

5. Can the China best American Type Axle Rear Steer Axle be customized to suit specific requirements?

Yes, the China best American Type Axle Rear Steer Axle can be customized to suit the specific needs of our customers. Please contact us to discuss your requirements and to receive a quote.

Our company offers a wide range of other high-quality industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing our customers with the highest-quality products, the best prices, and the most thoughtful service possible. Customers are welcome to customize their products with drawings and samples.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.